You might not expect a Pennsylvania turbine builder to have much in common with California astronomers, but photographs in Hagley’s collections reveal a unique connection. In the 1930s, employees of the Westinghouse Electric Company participated in one of the most visionary scientific projects of the twentieth century, the building of the Hale Telescope. To be located on Palomar Mountain 90 miles southeast of Los Angeles and administered by the California Institute of Technology, the 200-inch instrument would be the largest in the world and be used by astronomers to ponder the expansion of the universe.

The brainchild of astronomer and public advocate for science, George Ellery Hale, the telescope project received funding from the Rockefeller Foundation in 1928 and came with numerous technological and engineering challenges. First, Hale and fellow members of an appointed Observatory Council selected Corning Glass Works in New York to handle the casting of a 200-inch mirror for the telescope, at the time the largest single piece of glass ever made. After confirming that such a mirror could even be cast, the council faced another test in designing a mounting system and structural tube assembly for the massive mirror. Together, these components needed to support the mirror, grant the instrument access to the entire sky, and allow the telescope to function with extreme accuracy. Captain Clyde S. McDowell, appointed to superintend construction work, described just how accurate the million-pound telescope needed to be: “Errors in sighting must not be larger than the angle which would be made by drawing lines 3 miles long from a point to the top and bottom of a 25 cent piece.” Quite a tall order!

The final designs included a 55-foot optical tube assembly newly developed by Mark Serrurier of Caltech and an equatorial mount featuring a 46-foot open horseshoe bearing which would allow the telescope unobstructed views of the sky while compensating for the rotation of the Earth. Both components would be made of steel, and with the designs selected the Observatory Council sought out companies with the skills and facilities to execute their unique and complex order. Westinghouse Electric Company fit the bill, and in 1936 the company received the construction contract. To approach the engineering challenges of the design, a team of four Westinghouse engineers built a 1/32 working scale model of the telescope with celluloid. The team used polarized light to locate places of strain on the model and measured deflections and distortions with ultra-sensitive micrometers electrically connected to a microammeter. They also decided to implement an oil film bearing commonly used in Westinghouse turbo-generators to minimize friction and increase the telescope’s accuracy.

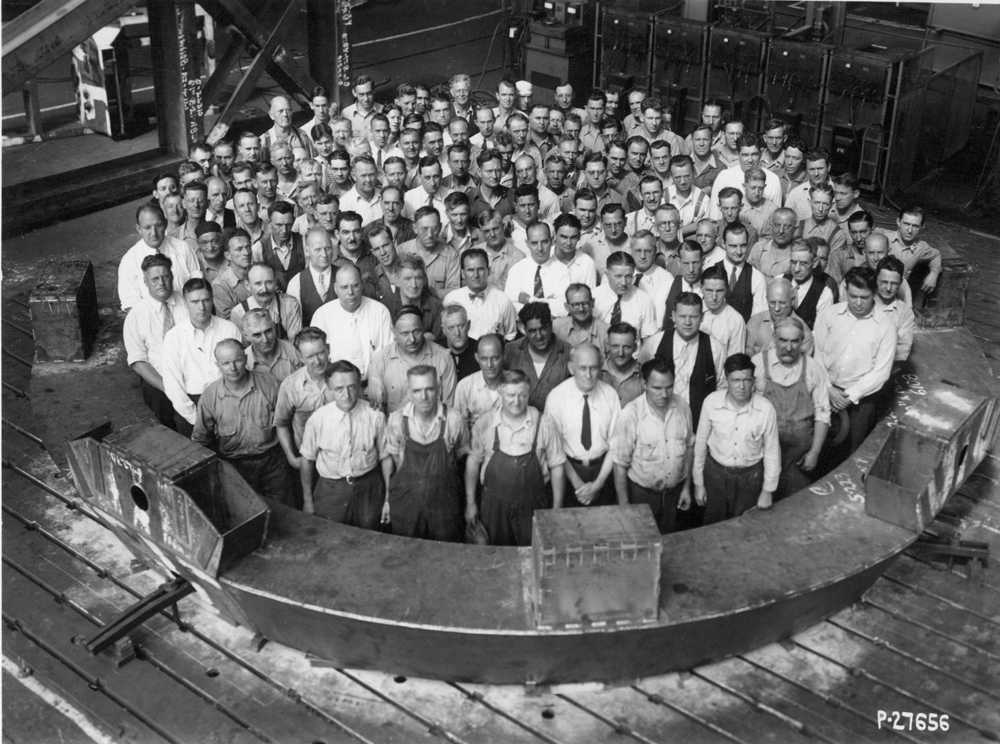

The engineering complete, Westinghouse employees more accustomed to building large industrial steam turbines then set to work constructing what was to become an instrument capable of observing objects a billion light years away. Although most of the machining was accomplished using tools already available at the Lester, Pennsylvania turbine plant, some of the construction called for special equipment. Parts of the tube assembly were so wide that workers had to combine a planer and a milling machine to attain the required reach, and the horseshoe bearing was so massive that it could only be accommodated by a giant floor mill at a different Westinghouse plant in East Pittsburgh. Finally, a special annealing oven capable of reaching 1200° F had to be built to remove internal stresses in the steel resulting from electrically welding the fabricated parts.

On April 30, 1937, in a ceremony attended by such scientific celebrities as Albert Einstein and Robert Millikan, a forty-eight-year veteran employee of Westinghouse, William Ladley, tightened the last bolt in the 75-ton tube assembly. The horseshoe-mount was completed shortly thereafter and, as their final contribution, Westinghouse employees loaded the various components on rail cars headed for the Philadelphia docks. From there, they were shipped via the Panama Canal and finally trucked to Palomar Mountain and assembled inside the newly constructed observatory.

Although the construction and assembly of the steel framework were now complete, the 200-inch mirror proved to be a source of major delay. Corning Glass Works had successfully cast and transported the mirror to the Caltech optical shop in 1936, but grinding and polishing challenges as well as World War II prevented the mirror from being ready for transport to the Palomar site for another 11 ½ years.

Ten years after George Hale’s death, the telescope was finally dedicated in Hale’s honor on June 3, 1948, and research with the telescope began in earnest in November 1949. Thanks in part to the contribution of Westinghouse machinists, astronomers could now gaze farther into the universe than ever before. In the ensuing decades, the Hale Telescope has been used to study the expansion of the universe, the formation of galaxies, stellar evolution, and myriad other topics. Although it is no longer the largest in the world, the Hale Telescope is still used by scientists today as a vital player in astronomical discovery.

The Hale Telescope construction photographs and others from the collection of Westinghouse Electric Corporation Steam Division photographs have been digitized and can be explored here in Hagley’s newly relaunched Digital Archives.

Angela Schad is a contractor for the library working on Digital Archives development