Food, grocery, and other packaging materials have evolved substantially over the past 100 years, and they continue to change, faster than ever.Some of the current change is accelerated by awareness of environmental issues like sustainability and the biodegradation (or not) of plastics. In the past, change was influenced by new discoveries in the chemistry laboratory, as well as changes in advertising promoting modern lifestyles.

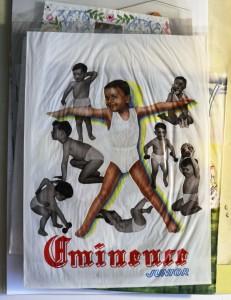

Hagley has a small collection of printed packaging materials from Milprint Inc. that shows how cellophane and other wrappers evolved through the mid-twentieth century. Some of the interesting cellophane materials were recently in the conservation lab for examination.

Initially, DuPont imported cellophane made in Europe for sales in the United States, but after acquiring rights to become the sole manufacturer and distributor in the U.S., DuPont increasingly extolled the benefits of cellophane for food packaging and textiles in its own DuPont Magazine. (An antitrust case was filed in 1947 regarding the cellophane monopoly).

Beginning in 1927, DuPont developed and introduced moisture-proof cellophane, making it more versatile for protecting certain foods, like bread and cookies. Stores and consumers desired pristine products with longer shelf life and visual appeal.

Cellophane was one packaging material that had the distinct advantage of both protecting freshness and projecting an image of sterility, while allowing the consumer to see the product through the packaging.

Although DuPont was the major worldwide producer of cellophane—in 1938, 25% of DuPont’s profits came from cellophane—it cannot take credit for its invention. Instead, the credit goes to the British firm of Cross, Bevan, and Beadle, who created viscose in 1892.

Viscose is produced with dissolved cellulose fibers that are spun into rayon threads or formed into a transparent sheet (cellophane). The method for forming viscose into a transparent film occurred later in Switzerland and France where the original patent was held by La Cellophane.

Technically, these products are not plastics but regenerated cellulose, and they are manmade semi-synthetics. Cellulose does have one thing in common with oil-based plastics: they are all polymers.

Both rayon fabric and cellophane film are currently touted as sustainable, because they are produced with natural plant fibers, rather than petroleum. Recently many clothing articles made of rayon have been marketed as “bamboo”, as if the fibers from bamboo could be spun into thread!

Although rayon and cellophane come from plants, the methods used to produce them require significant amounts of hazardous and caustic chemicals including carbon disulfide needed to dissolve the plant fibers. Perhaps mention of organic fibers should invoke thoughts of organic chemistry, rather than environmental sustainability.

Semi-synthetic materials are also marketed as biodegradable. While, on the bright side, cellophane and rayon materials that are disposed of can indeed decompose, but on the dim side, natural degradation is a problem for conservators and institutions wishing to preserve these materials. Regenerated cellulose is susceptible to water, mold,and insect damage. Thankfully, it is not on the list of the most unstable plastics, which includes cellulose acetate, cellulose nitrate, p.v.c., and polyurethane.

The moisture-proof coating applied to cellophane typically included cellulose nitrate, until 1947 when co-polymer coatings were invented. Other variations in the coatings included wax and resins that allowed for heat sealing of packaging. These coatings were reportedly only 1-2 microns thick. It is not well known how great an influence these coatings have on the stability of the cellophane film.

Some of the materials in the Milprint collection have distortions and yellowing that may be attributable to deterioration and shrinkage of the cellulose nitrate lacquer. However, most of them do not yet exhibit any ill effects. Their preservation will depend on storing them in low temperature and moderate humidity storage.

In the near future, the crinkly cellophane wrapper may make a return to the grocery as part of a wave of green “earth friendly” packaging. At least it won’t be as noisy as the biodegradable polylactic acid bags that surfaced in snack aisles in 2011.

The Leonard W. Walton Collection on Printing and Packaging (Acc. 2430) is located in the Manuscripts and Archives Collection at Hagley Museum and Library.

Laura Wahl is the Library Conservator at Hagley Museum and Library.